Guardrails

Guardrail Guidelines

The criteria for evaluating railing systems is changing. Don't fall behind your competitors in the re-evaluation of your guardrails.

The Association of Professional Engineers and Geoscientists of BC (APEGBC) published a new set of guardrail guidelines in May 2013. The loading on railings stated in the National Building Code of Canada has not changed in decades; however the new APEGBC railing guidelines proposes testing that significantly changes how guardrail systems are evaluated. Higher strengths are now required, particularly when dealing with brittle failure modes.

Also included in the Guidelines are details regarding Continuity of Responsibility requiring that designers are responsible for a competent load path and that a complete guard assembly is possible. There must be a "complete structural assembly including an appropriate attachment to the base structure."

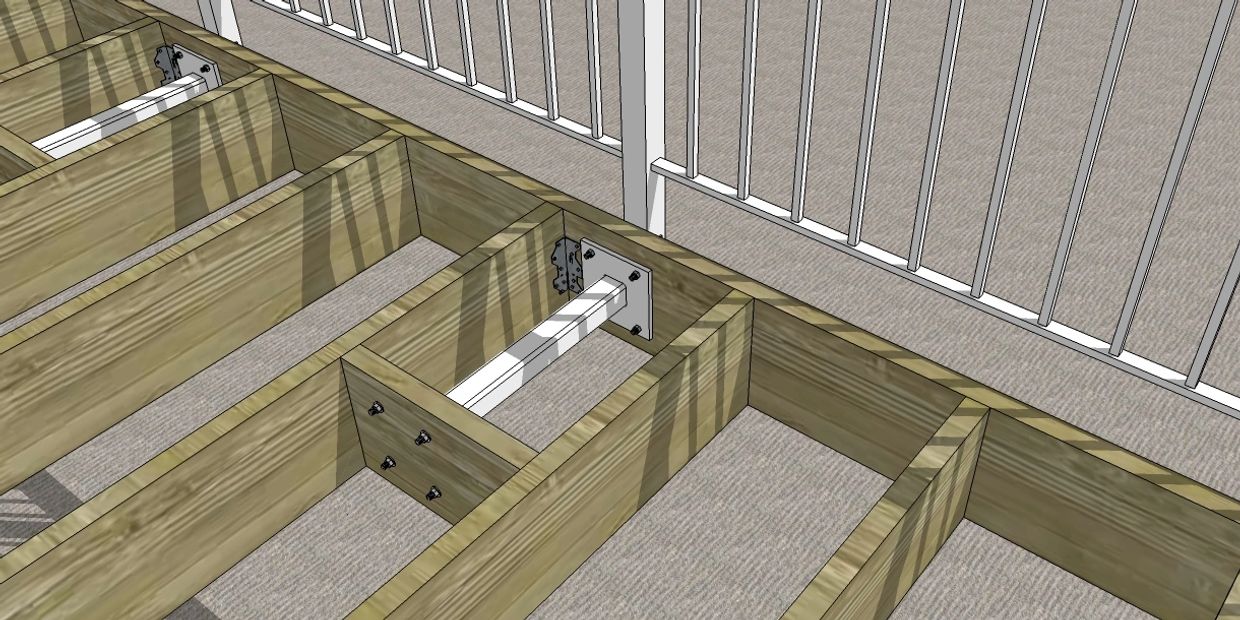

Latera would be pleased to assist you with the re-evaluation of your guardrail system to the latest evaluation criteria. Our patented "Breyce" can provide the required base structure attachment for wood construction.

Introducing the Breyce

This patented* device is an ideal addition to railing manufacturers' product line for customers that want a simple bracket to add stiffness and strength to their railings. Architects, specify the Breyce to ensure code compliance of the structural aspects of guardrails.

The code-required load of 50 lbs per foot at the top of a 42" high rail, at 6'-0" post spacing, results in a torque of 1050 ft-lbs. A post attachment of four bolts in a 3" x 3" pattern results in a bolt tension of 2100 lbs. This bolt tension is not a problem for concrete or steel, but wood structures can be problematic.

There are many scenarios in which guardrails can fail:

- Lag screws pull out

- Bolt and washers only secure the railing to a weak rim board

- Straps cause problems with sheathing installation, take time to nail, and still require the use of bolts and washers.

*US 2014/0339487, CA 2847200, WO 2013033826

The Breyce Advantage

- One component

- Engineered to resist code loads

- Forces on the timber components are reduced

- Creates a stiffer railing system

- Can be fabricated from typical aluminum tube and plate

- Wider post spacing is possible

- Can be adapted for both surface and fascia mounted railings

- Ideal for balconies with aluminum or vinyl soffits

In railing attachment, as with all structural design, the chain principle applies: the weakest link fails first. The Breyce provides a complete solution to transfer the guard load directly into the structure, eliminating the weak links.

Contact Cameron Robinson, P.Eng. at cam@latera.ca for licensing details and engineering support.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.